Understanding how to use pulse engine tachometer can significantly enhance the efficiency and accuracy of your projects. This sophisticated device is a must-have for Industry QA Professionals, and its applications span across various sectors.

The primary goal of this article is to guide you through the complete process of utilizing a pulse engine tachometer, ensuring you get the most out of this technology.

What is a Pulse Engine Tachometer?

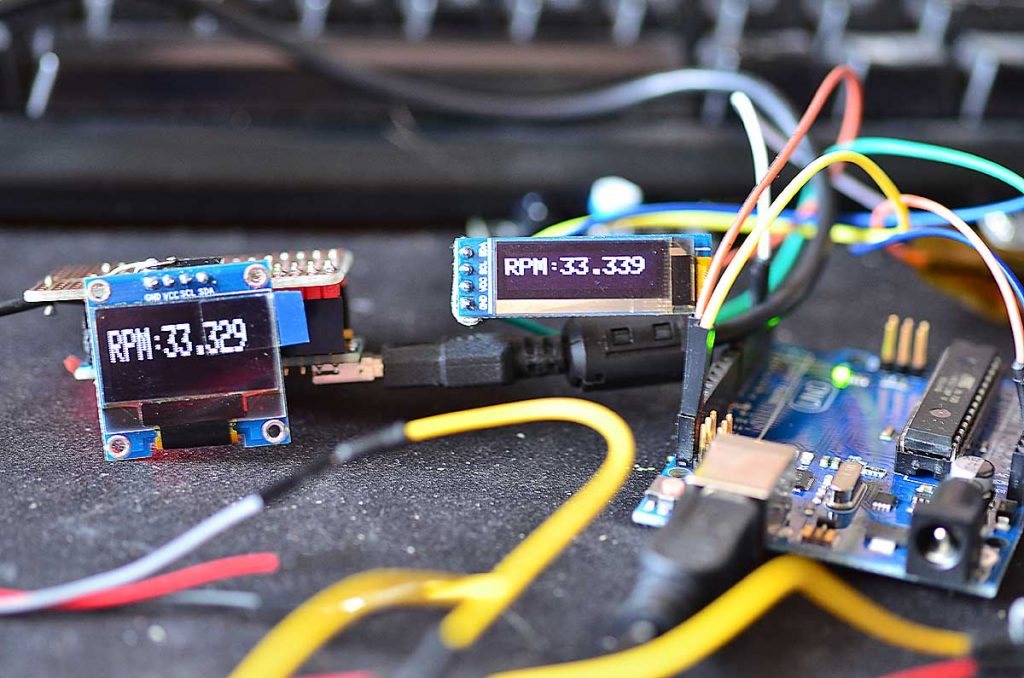

A pulse engine tachometer is an instrument used to measure the rotation speed of a shaft or disk, as in a motor or other machine. It is an essential tool for anyone needing precise tachometer readings.

Why Use a Pulse Engine Tachometer?

This device offers numerous advantages including high accuracy, versatility, and ease of use. It is approved for applications in various industries, from automotive to aerospace, making it a terrific tool for QA professionals.

Types of Pulse Engine Tachometers

Analog Tachometers

Digital Tachometers

Contact vs Non-Contact Tachometers

How Does a Pulse Engine Tachometer Work?

Basic Principles

Component Breakdown

Reading and Interpreting Data

Common Applications

Automobile Industry

Aerospace

Manufacturing and QA

Maintenance and Calibration

Regular maintenance and calibration ensure your tachometer delivers accurate readings. Learn more about the importance of calibration.

FAQs

How to Install a Pulse Engine Tachometer?

Installing a pulse engine tachometer involves connecting the device to the engine and correctly configuring the sensors. Always refer to the user manual for specific guidelines.

What Are the Common Issues and Troubleshooting Tips?

Issues can range from inaccurate readings to device malfunctions. Regular calibration and following the manufacturer’s troubleshooting guide can help solve most problems.

How Important is Regular Calibration?

Regular calibration is crucial for maintaining the accuracy of your tachometer, ensuring reliable and precise measurements.Read more