When it comes to the realm of milling machines, one can’t help but ponder over the endless varieties and their respective applications. So, the big question arises: What are the three basic types of milling machines? This is a fundamental query, especially for Industry QA Professionals who frequently deal with these versatile machines.

In this article, we will delve deep into the three basic types of milling machines, namely the vertical milling machine, the horizontal milling machine, and the universal milling machine. Each of these machines has its unique features, capabilities, and applications, making them indispensable in the modern manufacturing landscape.

1. Vertical Milling Machines

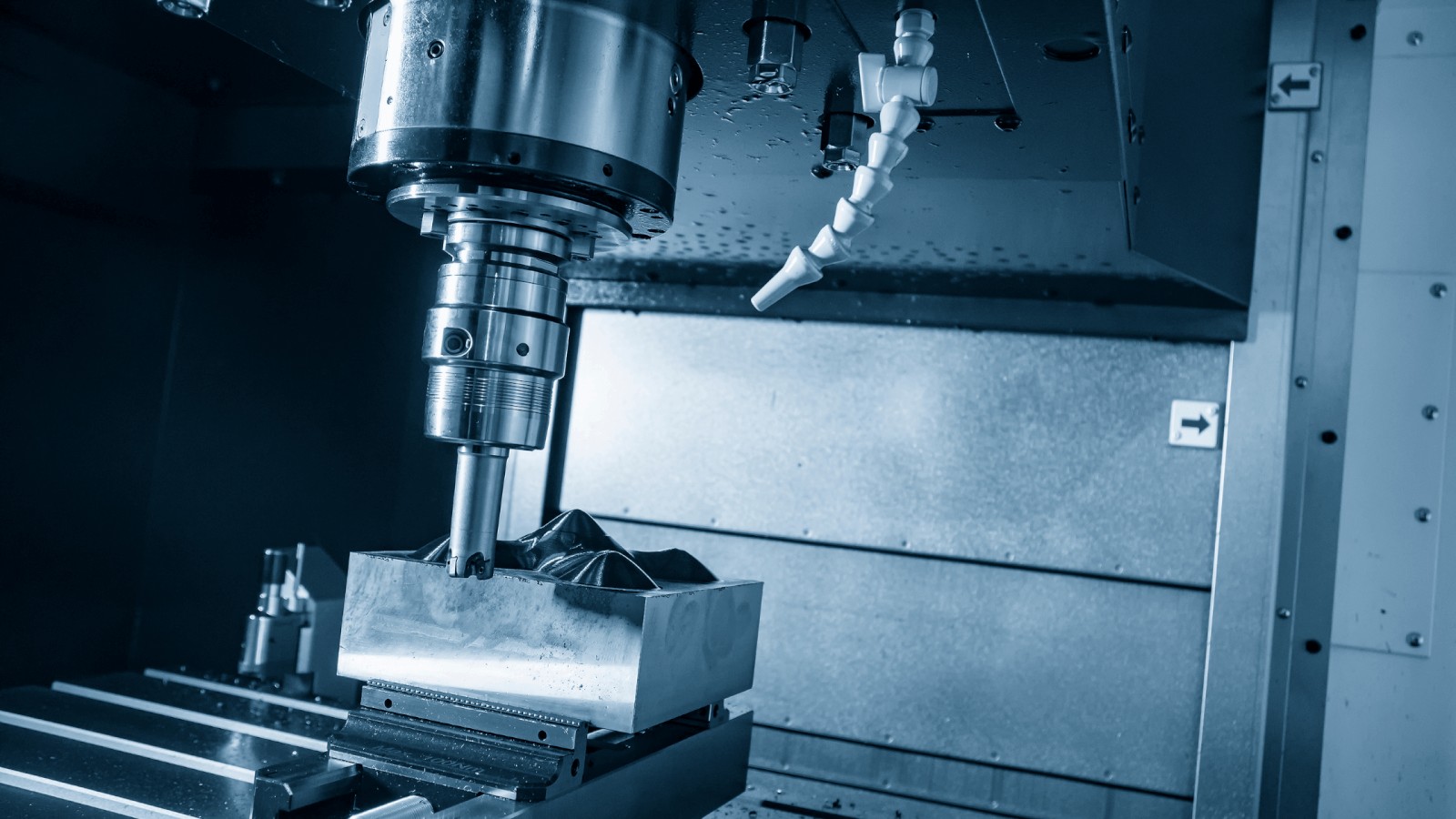

The first on our list is the vertical milling machine. As the name suggests, this type of milling machine has a vertically oriented spindle, which holds and rotates the cutting tool. This vertical orientation allows for precise and accurate milling operations on various materials.

Key Features of Vertical Milling Machines

Vertical milling machines are equipped with a swivel head, allowing for angular cutting and drilling operations. They are highly versatile and can perform tasks like end milling, face milling, and drilling with ease. Their compact design makes them suitable for small to medium-sized workpieces.

Common Applications

Vertical milling machines find extensive use in industries such as automotive, aerospace, and electronics. They are ideal for producing precision components like gears, molds, and dies. Additionally, they are commonly used in prototyping and small-scale production operations.

For high-speed paint and coating application inspection, vertical milling machines play a crucial role in ensuring the quality and uniformity of the applied coatings. Learn more about related industrial inspections at paint and coating inspection

2. Horizontal Milling Machines

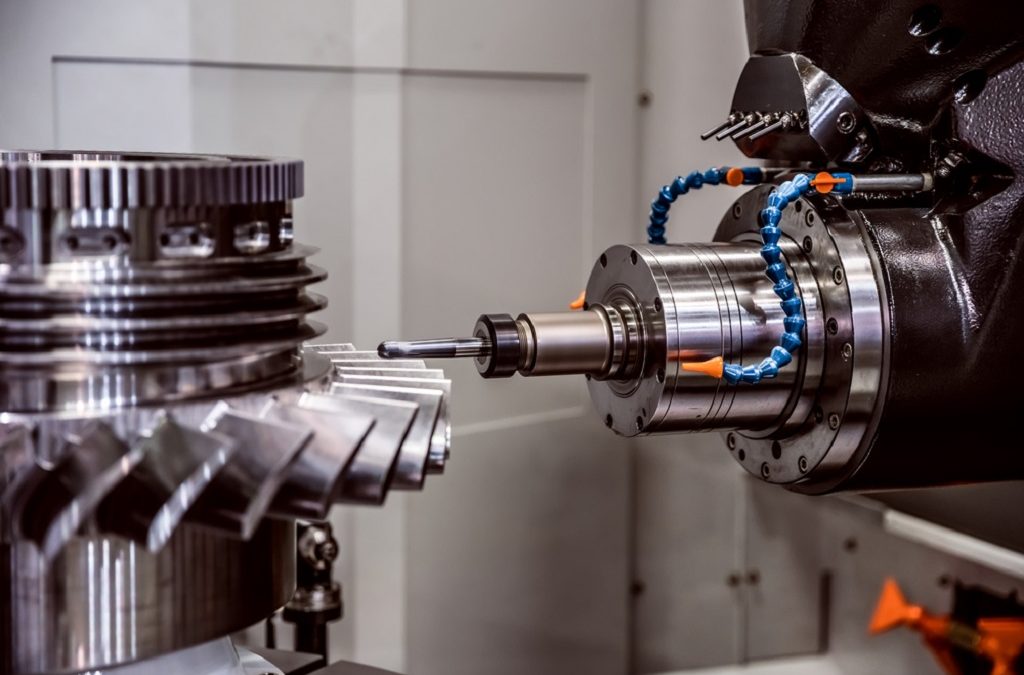

The second type in our exploration of milling machines is the horizontal milling machine. Unlike its vertical counterpart, this machine has a horizontally oriented spindle, which supports the cutting tool. This orientation allows for a different set of machining operations and offers unique advantages.

Key Features of Horizontal Milling Machines

Horizontal milling machines are characterized by their ability to perform heavy-duty cutting operations. They are equipped with a horizontal arbor that supports multiple cutting tools simultaneously. This feature allows for efficient machining of large workpieces and the production of complex shapes in a single setup.

Common Applications

Horizontal milling machines are widely used in industries such as oil and gas, shipbuilding, and heavy machinery manufacturing. They excel in tasks that require high material removal rates and precise milling operations. Typical applications include machining large components like engine blocks, transmission housings, and structural parts.

Horizontal milling machines are essential for high-speed semiconductor manufacturing inspection, where precision and accuracy are paramount. Discover more about this application at semiconductor inspection

3. Universal Milling Machines

The third and final type of milling machine on our list is the universal milling machine. This versatile machine combines the features of both vertical and horizontal milling machines, making it a powerful tool in the hands of skilled machinists.

Key Features of Universal Milling Machines

Universal milling machines come with a swiveling table that allows for angular milling operations. They are equipped with both vertical and horizontal spindles, providing users with the flexibility to switch between different machining techniques. This adaptability makes them suitable for a wide range of applications.

Common Applications

Universal milling machines are commonly used in tool and die making, metalworking, and manufacturing industries. They are ideal for tasks that require intricate and precise machining, such as producing molds, cutting gears, and shaping complex surfaces.

For advanced stroboscopic event detection in semiconductor wafer polishing, universal milling machines offer the precision and adaptability needed. Explore more about this technology at stroboscopic detection

The Importance of Milling Machines in Modern Manufacturing

Milling machines, whether vertical, horizontal, or universal, play a pivotal role in modern manufacturing. They are essential for producing a wide range of components and products with high precision and accuracy. These machines are the backbone of industries like automotive, aerospace, electronics, and heavy machinery manufacturing.

Advancements in Technology

With advancements in technology, milling machines have become more sophisticated and capable. Computer numerical control (CNC) technology has revolutionized the machining industry, allowing for automated and highly precise milling operations. CNC milling machines have enhanced productivity, reduced human errors, and enabled the production of complex geometries with ease.

For more information on milling machines and their applications, you can visit this informative page.

Choosing the Right Milling Machine for Your Needs

Selecting the right milling machine depends on several factors, including the type of material to be machined, the complexity of the workpiece, and the desired level of precision. It is essential to consider these factors to ensure optimal performance and cost-effectiveness.

Material Considerations

Different materials require different milling techniques and tools. For example, machining softer materials like aluminum and plastics may require a vertical milling machine, while tougher materials like steel and titanium may benefit from the capabilities of a horizontal milling machine.

Complexity of Workpiece

The complexity of the workpiece also plays a crucial role in determining the suitable milling machine. Simple shapes and flat surfaces can be easily machined on a vertical milling machine, while complex geometries and intricate details may require the versatility of a universal milling machine.

Precision Requirements

The level of precision required for the finished product is another critical factor. For high-precision components, CNC milling machines are the preferred choice. These machines offer unparalleled accuracy and repeatability, ensuring consistent quality in every production run.

Future Trends in Milling Machine Technology

The future of milling machines looks promising, with continuous advancements in technology driving innovation in the field. Here are some key trends to watch out for:

1. Integration of Artificial Intelligence

Artificial intelligence (AI) is set to revolutionize the milling industry. AI-powered milling machines can optimize cutting parameters in real-time, improving efficiency and reducing tool wear. Machine learning algorithms can also predict maintenance needs, minimizing downtime and increasing productivity.

2. Additive Manufacturing Hybrid Machines

Additive manufacturing, commonly known as 3D printing, is being integrated with traditional milling machines to create hybrid systems. These hybrid machines combine the benefits of both subtractive and additive manufacturing, enabling the production of complex parts with minimal material waste.

3. Internet of Things (IoT) Connectivity

IoT connectivity allows milling machines to communicate with other devices and systems, creating a smart manufacturing environment. This connectivity enables real-time monitoring, remote diagnostics, and predictive maintenance, enhancing overall efficiency and productivity.

FAQs

1. What is a vertical milling machine used for?

Vertical milling machines are used for a wide range of tasks, including end milling, face milling, drilling, and angular cutting. They are ideal for producing precision components like gears, molds, and dies in industries such as automotive, aerospace, and electronics.

2. Can horizontal milling machines perform heavy-duty cutting?

Yes, horizontal milling machines are known for their ability to perform heavy-duty cutting operations. They are equipped with a horizontal arbor that supports multiple cutting tools, making them suitable for machining large workpieces and producing complex shapes.

3. What makes universal milling machines versatile?

Universal milling machines are versatile because they combine the features of both vertical and horizontal milling machines. They come with a swiveling table and dual spindles, allowing for a wide range of machining operations and providing flexibility for intricate and precise tasks.

In conclusion, understanding what are the three basic types of milling machines and their applications is crucial for Industry QA Professionals and anyone involved in manufacturing. These machines are the backbone of modern industries, driving innovation and enabling the production of high-precision components. As technology continues to advance, the future of milling machines looks brighter than ever, promising even greater capabilities and efficiencies. For more information, you can read about milling (machining) on Wikipedia.