In the ever-evolving world of quality assurance, understanding the frequency response of inspection sensors is crucial. For Industry QA Professionals, this knowledge can significantly enhance the precision and reliability of inspections. The frequency response is a measure of a sensor’s ability to accurately detect and respond to various defects during inspections. By grasping these concepts, QA professionals can ensure their inspections are not only efficient but also meet the highest standards of quality.

What is Frequency Response?

At its core, the frequency response of a sensor is how it reacts to different frequencies of input signals. This reaction is vital because it determines the sensor’s ability to detect defects or changes in materials or systems being inspected. In the context of inspection sensors, understanding this response can mean the difference between identifying a critical flaw and missing it entirely.

Importance of Frequency Response in Inspection

For QA professionals, the importance of frequency response can’t be overstated. It is the foundation upon which accurate and reliable inspections are built. By understanding how a sensor’s frequency response works, professionals can optimize their inspection processes, ensuring every detail is captured accurately. This knowledge is not just theoretical; it has practical applications that directly impact the quality of inspections and, subsequently, the safety and reliability of products and systems.

Measuring Frequency Response

To effectively utilize frequency response, one must first know how to measure it. This involves analyzing how a sensor responds to different frequencies and comparing these responses. Through such measurement, QA professionals can identify any discrepancies or limitations in a sensor’s capabilities, allowing for adjustments and improvements in inspection processes.

Factors Affecting Frequency Response

Several factors can impact the frequency response of an inspection sensor. These include the sensor’s design, the materials it is inspecting, and the environmental conditions during inspection. Understanding these factors helps QA professionals anticipate potential challenges and adjust their methods accordingly. For instance, in environments with high levels of interference, special considerations must be taken to ensure accurate readings.

Design and Material Considerations

The design of a sensor plays a significant role in its frequency response. Different designs may be better suited for certain frequencies or types of inspections. Similarly, the material being inspected can affect how a sensor responds. Some materials may absorb or reflect certain frequencies, impacting the sensor’s ability to detect changes or defects.

Applications in Industry

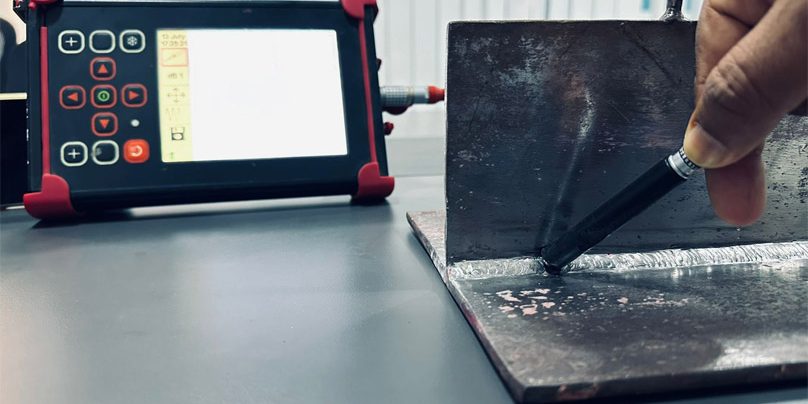

The frequency response of inspection sensors finds applications across various industries. In manufacturing, it is critical for ensuring product quality and safety. In construction, it helps in identifying structural weaknesses. Each application requires a tailored approach to frequency response, highlighting the need for specialized knowledge and expertise among QA professionals.

Manufacturing Applications

In the manufacturing sector, the frequency response is crucial for maintaining high standards of quality. By using sensors with appropriate frequency responses, manufacturers can detect defects early, reducing waste and ensuring products meet specifications. This application is vital for maintaining competitive advantage and customer satisfaction.

Construction and Infrastructure

In construction, the use of sensors with the right frequency response can prevent catastrophic failures by identifying structural flaws before they become critical. This proactive approach is essential for ensuring the safety and longevity of buildings and infrastructure projects.

Challenges and Solutions

While understanding the frequency response of inspection sensors offers numerous benefits, it also presents challenges. These include dealing with complex data, ensuring calibration accuracy, and adapting to different inspection environments. However, these challenges can be overcome through continuous learning, collaboration, and the use of advanced technologies.

Overcoming Calibration Issues

Calibration is a common challenge in ensuring accurate frequency response. Regular calibration and maintenance of sensors are crucial for ensuring reliability. By establishing a routine calibration schedule, QA professionals can maintain the precision and accuracy of their inspections.

Adapting to Environmental Variables

Environmental factors such as temperature, humidity, and electromagnetic interference can affect a sensor’s frequency response. By understanding these variables, QA professionals can implement strategies to mitigate their impact, ensuring consistent and reliable inspection results.

Future Trends in Frequency Response Technology

As technology advances, so does the potential for improving the frequency response of inspection sensors. Emerging technologies like machine learning and AI are being integrated into inspection processes, offering new ways to enhance sensor accuracy and efficiency. These trends present exciting opportunities for QA professionals to stay ahead in their field.

Machine Learning and AI

Machine learning and AI technologies are revolutionizing how frequency response is utilized in inspections. These technologies can analyze large datasets quickly, identifying patterns and anomalies that might be missed by traditional methods. This capability enhances the accuracy and efficiency of inspections.

Integration with IoT

The integration of the Internet of Things (IoT) with inspection sensors is another trend shaping the future of frequency response. IoT-enabled sensors can provide real-time data, allowing for immediate analysis and decision-making. This integration enhances the overall inspection process, providing more accurate and timely results.

Conclusion

Understanding the frequency response of inspection sensors is essential for Industry QA professionals. It is a critical component of effective quality assurance, impacting the accuracy and reliability of inspections. By mastering this concept, professionals can enhance their inspection processes, ensuring high-quality outcomes in various industries.

FAQ Section

What is the typical frequency range for inspection sensors?

The typical frequency range for inspection sensors varies depending on the application. For example, ultrasonic testing commonly uses frequencies between 1 MHz to 10 MHz. Understanding the specific requirements of an inspection helps in selecting the appropriate frequency range.

How often should inspection sensors be calibrated?

Regular calibration is crucial for maintaining the accuracy of inspection sensors. It is recommended to calibrate sensors at least once a year or more frequently if they are used in critical applications. [Learn more about calibration schedules](https://www.stansomatic.com/how-often-should-stamping-tools-be-inspected/) here.

Can environmental factors affect sensor frequency response?

Yes, environmental factors like temperature, humidity, and electromagnetic interference can impact a sensor’s frequency response. Understanding these factors allows QA professionals to implement strategies to mitigate their effects, ensuring accurate and reliable inspection results.

Further Reading

For more information on optimizing sensor frequencies, visit [Optimal Frequency for Crack Detection](https://strobox.ai/optimal-frequency-for-crack-detection/) here. Additionally, insights on improving inspection accuracy through synchronization can be explored at [Synchronization Improves Inspection](https://strobox.ai/how-synchronization-improves-inspection-accuracy/) here.

This article contains affiliate links. We may earn a commission at no extra cost to you.