The automotive industry is constantly evolving, and technology has dramatically transformed many areas, including how we ensure car paint quality. Ensuring Car Paint Quality with Automated Inspection Systems is a significant breakthrough that incorporates advanced technology to provide tremendous benefits. This innovation has not only improved the efficiency of the paint inspection process but has also delighted manufacturers with its precision and reliability.

The Importance of Car Paint Quality

Car paint quality is a critical aspect of a vehicle’s overall appeal and longevity. High-quality paint protects the car’s body from corrosion and environmental damage. Consistently good paintwork also adds to the vehicle’s market value and customer satisfaction. Therefore, maintaining car paint quality isn’t just about aesthetics; it’s a crucial part of vehicle maintenance and brand reputation.

Traditional Methods of Car Paint Inspection

Historically, car paint inspection was a labor-intensive process primarily performed by trained human inspectors. These inspectors would visually examine each car for defects, such as color mismatches, runs, drips, and scratches. While skilled, human inspectors are subject to fatigue and variability, which can lead to inconsistent results. This is where technology has stepped in to provide a more reliable solution.

Introduction to Automated Inspection Systems

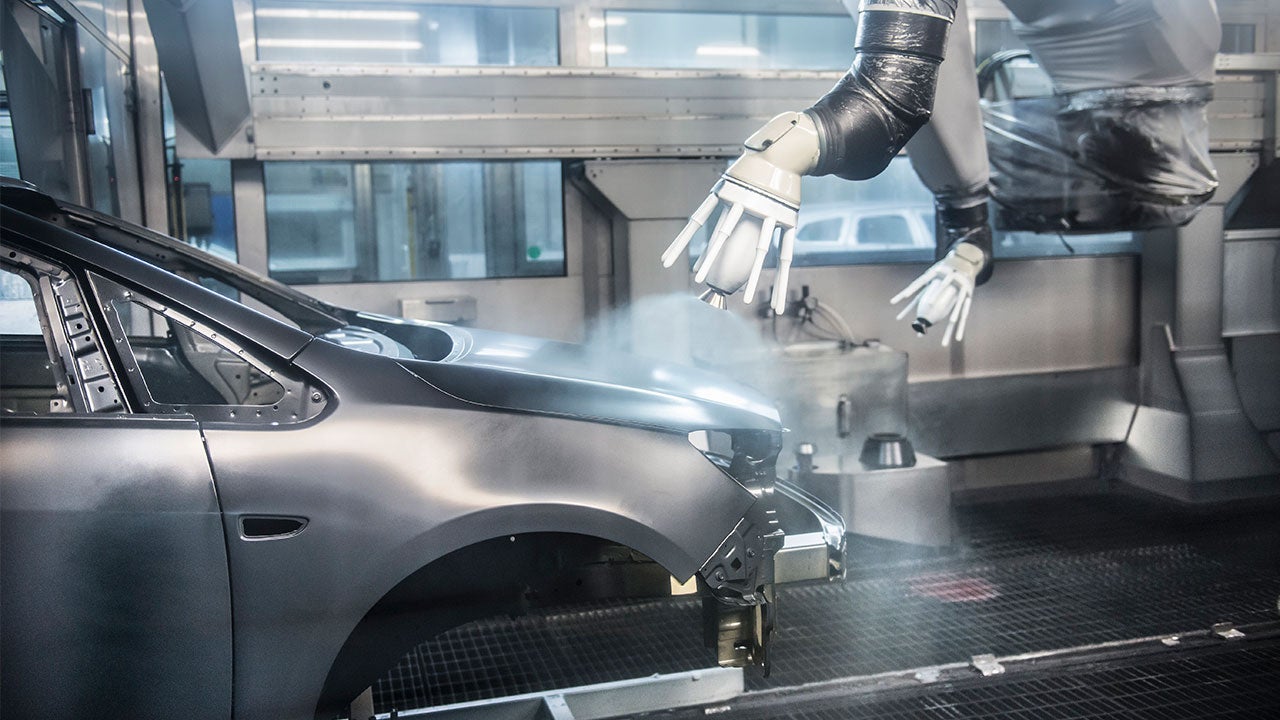

Automated inspection systems represent a significant leap forward in quality assurance for car paint. These systems use advanced imaging technologies, such as high-resolution cameras and laser scanners, to detect imperfections that are invisible to the human eye. They can quickly and accurately assess the entire surface of a vehicle, identifying even the smallest defects.

How Automated Inspection Systems Work

These systems work by capturing detailed images of the car’s surface as it moves along the production line. The images are then processed using sophisticated algorithms that can identify inconsistencies in color, texture, and gloss. Any deviations from the standard quality parameters are flagged for further inspection or rework.

Benefits of Using Automated Inspection Systems

Increased Efficiency

One of the most significant advantages of automated inspection systems is their ability to perform inspections at high speeds without compromising accuracy. This increased efficiency translates into faster production times and reduced labor costs.

Consistency and Reliability

Unlike human inspectors, automated systems do not suffer from fatigue or variability. They provide consistent and reliable results, ensuring that every car that leaves the production line meets the highest quality standards.

Advanced Features of Modern Inspection Systems

High-Resolution Imaging

Modern automated inspection systems are equipped with high-resolution cameras that capture every detail of the car’s surface. These images provide a precise and comprehensive view, allowing for the detection of even the smallest defects.

Laser Scanning Technology

Laser scanners are used to measure the paint’s thickness and detect any inconsistencies in the application. This technology ensures that the paint is applied evenly, providing a uniform and flawless finish.

Artificial Intelligence and Machine Learning

AI and Machine Learning play a crucial role in the effectiveness of automated inspection systems. These technologies enable the system to learn from past inspections and continuously improve its defect detection capabilities.

Implementation of Automated Inspection Systems

Integration with Existing Production Lines

Implementing an automated inspection system requires careful integration with existing production lines. This process involves calibrating the system to match the specific requirements of the production line and training staff to operate and maintain the new technology.

Training and Support

Manufacturers need to provide comprehensive training and support to their staff to ensure the successful implementation of automated inspection systems. This includes training on how to use the system, interpret the results, and perform necessary maintenance.

Case Studies and Examples

Automotive Industry Leaders

Several leading automotive manufacturers have successfully implemented automated inspection systems in their production lines. These companies have reported significant improvements in paint quality, reduced rework rates, and increased customer satisfaction.

Real-World Applications

One example of real-world application is Toyota’s use of automated inspection systems in their paint shops. Toyota’s commitment to quality is evident in their extensive use of technology to ensure every vehicle meets their high standards. (Source: Toyota Plant Tours)

Challenges and Solutions

Overcoming Initial Costs

One of the challenges faced by manufacturers is the initial cost of implementing automated inspection systems. However, these costs are often offset by the long-term benefits of increased efficiency and reduced rework.

Ensuring Compatibility

Another challenge is ensuring that the new systems are compatible with existing production lines. Manufacturers must work closely with system providers to ensure a seamless integration into their processes.

Future Trends in Automated Inspection Systems

Enhanced AI Capabilities

The future of automated inspection systems lies in the further advancement of AI and Machine Learning technologies. These advancements will enable even more precise defect detection and continuous improvement in quality assurance processes.

Integration with Industry 4.0

As the automotive industry moves towards Industry 4.0, the integration of automated inspection systems with other smart manufacturing technologies will become increasingly important. This integration will lead to more interconnected and efficient production lines.

Expanding Applications

Beyond car paint quality, automated inspection systems have the potential to be applied in other areas of automotive manufacturing, such as body panel fitment and interior quality checks. This expansion will further enhance overall vehicle quality.

Conclusion

In conclusion, Ensuring Car Paint Quality with Automated Inspection Systems represents a significant advancement in automotive manufacturing. These systems provide tremendous benefits, including increased efficiency, consistency, and reliability. As technology continues to evolve, we can expect even more innovative solutions to emerge, further enhancing the quality and appeal of vehicles worldwide.

Relevant Links

- Automotive Paint – Wikipedia

- Genetic Analysis

- Wafer Polishing

- Semiconductor Manufacturing

- Tachometer System

FAQ

What are automated inspection systems?

Automated inspection systems use advanced technologies like high-resolution cameras, laser scanners, and AI to detect defects in car paint quality.

Why is car paint quality important?

Car paint quality is crucial for protecting the vehicle from corrosion, enhancing its aesthetic appeal, and maintaining its market value.

How can AI improve car paint inspection?

AI improves car paint inspection by enabling automated systems to learn from past inspections and continuously improve their defect detection capabilities.