In the world of non-destructive testing (NDT), the term frequency ranges used in ultrasonic inspection is crucial. This technique is widely used across industries to evaluate the properties of a material without causing any damage. Understanding the different frequency ranges employed in ultrasonic inspection is essential for ensuring accurate and effective assessments.

Understanding Ultrasonic Inspection

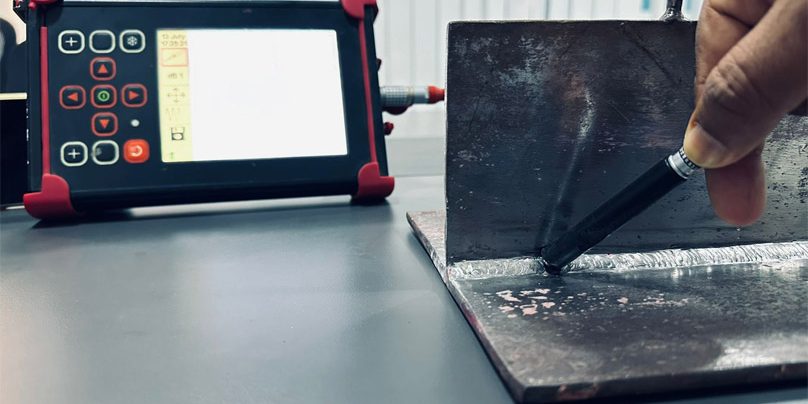

Ultrasonic inspection is a technique that uses high-frequency sound waves to detect imperfections or changes in properties within a material. This method is particularly advantageous because it does not compromise the material’s integrity.

Basic Principles of Ultrasonic Inspection

The principle behind ultrasonic inspection involves sending a sound wave into a material and analyzing the reflected waves. Any anomalies such as cracks or voids will reflect the waves differently, allowing inspectors to detect them.

The Role of Frequency in Ultrasonic Inspection

Frequency plays a pivotal role in ultrasonic inspection. It determines the penetration depth and resolution of the inspection. Different applications require different frequency ranges, which is why understanding these ranges is critical.

Low Frequency Ranges

Low frequencies, typically in the range of 0.5 to 2 MHz, are utilized when inspecting thicker materials. These frequencies allow for greater penetration depth, making them ideal for finding defects deep within a material.

High Frequency Ranges

High frequencies, ranging from 2 to 10 MHz, are used for detecting smaller imperfections near the surface of the material. They offer higher resolution, which is necessary for detecting fine details.

Applications of Different Frequency Ranges

Different industries use various frequency ranges based on their specific needs. For instance, the aerospace industry often uses high frequencies for detecting surface defects in aircraft components.

Automotive Industry

In the automotive sector, ultrasonic inspection helps in identifying flaws in critical components. Both high and low frequencies are used depending on the part being inspected.

Oil and Gas

For the oil and gas industry, low frequencies are preferred for inspecting pipelines and other thick materials to ensure there are no internal defects.

Advantages of Using Ultrasonic Inspection

Ultrasonic inspection offers numerous benefits, including its non-destructive nature, ability to provide detailed information about the material, and versatility across different industries.

Accuracy and Reliability

One of the key advantages is its accuracy. By choosing the appropriate frequency range, inspectors can obtain reliable data that is critical for safety and quality assurance.

Cost-Effectiveness

Despite the technology involved, ultrasonic inspection can be cost-effective, particularly when considering the potential costs of undetected defects.

Challenges and Considerations

While ultrasonic inspection is highly effective, it does have limitations. The choice of frequency, for example, must be made carefully to ensure the best results.

Material Properties

Different materials react differently to ultrasonic waves, which can affect the choice of frequency. Inspectors must consider the material’s density and thickness.

Equipment Limitations

Not all ultrasonic equipment can operate across the entire frequency range. This is something that must be considered during the planning phase of an inspection.

Future of Ultrasonic Inspection

As technology advances, the field of ultrasonic inspection continues to evolve. New techniques and equipment are being developed to enhance the capabilities of this vital inspection method.

Integration with AI

Artificial Intelligence (AI) is being integrated into ultrasonic inspection processes, offering enhanced data analysis and efficiency. Learn more about how AI is changing inspection processes here and here.

Improved Equipment

The equipment used in ultrasonic inspection is becoming more sophisticated, with better resolution and user-friendly interfaces.

Conclusion

Understanding the frequency ranges used in ultrasonic inspection is crucial for industry professionals. By selecting the correct frequency range, inspectors can ensure the integrity and safety of materials across various industries.

FAQ Section

What is the typical frequency range used in ultrasonic inspection?

The frequency range typically used in ultrasonic inspection varies from 0.5 MHz to 10 MHz, depending on the material and the type of inspection required.

Why is frequency important in ultrasonic inspection?

Frequency is important because it affects the depth of penetration and resolution of the inspection, which are critical for identifying defects accurately.

Can ultrasonic inspection be used on all materials?

While ultrasonic inspection is versatile, not all materials are suitable. The material’s acoustical properties will determine the effectiveness of the inspection.

For more detailed information on inspection frequencies and schedules, you can visit this external resource.

This article contains affiliate links. We may earn a commission at no extra cost to you.