In the world of industry quality assurance, understanding how frequency influences inspection results is crucial. Inspections are integral to maintaining standards, ensuring safety, and boosting productivity. The frequency of these inspections plays a pivotal role in determining their efficacy. This article delves into the intricate relationship between inspection frequency and the results they yield, providing insights for industry professionals seeking to optimize their inspection processes.

Importance of Inspection Frequency

Inspection frequency refers to how often inspections are conducted within a given timeframe. It is a critical factor that impacts the thoroughness and reliability of the inspection results. Different industries have varying requirements for inspection frequency based on regulatory standards, operational needs, and risk factors.

For instance, industries dealing with hazardous materials or high-risk environments may require more frequent inspections to ensure compliance and safety. Conversely, industries with stable, low-risk operations might opt for less frequent inspections.

Factors Determining Inspection Frequency

Regulatory Requirements

Many industries are governed by strict regulatory standards that dictate the minimum frequency of inspections. These regulations are designed to protect both workers and consumers by ensuring that all safety and quality standards are met consistently. For example, food and drug industries are subject to stringent inspection schedules to prevent contamination and ensure consumer safety.

Operational Risk

The level of risk associated with a particular operation also determines inspection frequency. High-risk operations, such as those involving heavy machinery or toxic substances, necessitate more frequent inspections to mitigate potential hazards. On the other hand, low-risk operations may require less frequent inspections, allowing resources to be allocated elsewhere.

Cost-Benefit Analysis

Organizations often perform cost-benefit analyses to determine the optimal inspection frequency. This involves weighing the costs of conducting inspections against the potential costs of failures or non-compliance. Frequent inspections may incur higher immediate costs but can prevent costly failures and legal penalties in the long run.

Impact of Inspection Frequency on Results

Understanding how frequency influences inspection results can help organizations strike a balance between thoroughness and efficiency. Too infrequent inspections can lead to overlooked issues, while overly frequent inspections may result in unnecessary resource expenditure.

Detection of Issues

Frequent inspections increase the likelihood of detecting issues early, allowing for timely intervention. This proactive approach can prevent minor problems from escalating into major failures, ensuring continuity in operations.

Resource Allocation

Optimizing inspection frequency helps in better resource allocation. By determining the right frequency, organizations can ensure that resources are used efficiently without compromising on safety and quality.

Consistency and Reliability

Regular inspections contribute to consistency and reliability in operations. They ensure that all processes are aligned with industry standards and that any deviations are promptly addressed. This consistency fosters trust among stakeholders and enhances the organization’s reputation.

Challenges in Determining Optimal Inspection Frequency

Balancing Cost and Quality

One of the primary challenges in determining inspection frequency is balancing cost and quality. Organizations must find a frequency that ensures quality without incurring excessive costs. This requires a thorough understanding of the industry, operational risks, and regulatory requirements.

Adapting to Changes

Industries are dynamic, and factors influencing inspection frequency can change over time. Organizations must remain adaptable and be ready to adjust their inspection schedules in response to changes in regulations, technology, and market demands.

Technological Advancements in Inspection Processes

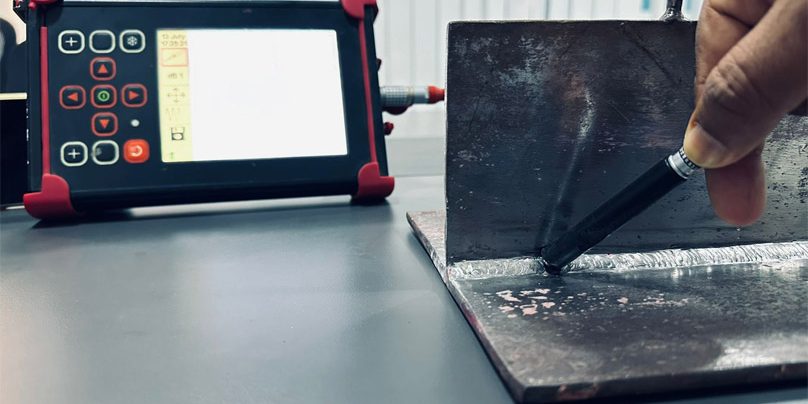

Technological advancements have revolutionized inspection processes, offering new opportunities to optimize inspection frequency. Innovations in synchronization technologies, such as those discussed in synchronization technologies, enable more precise and efficient inspections.

Automated Inspection Systems

Automated inspection systems leverage technology to conduct inspections more frequently and accurately. These systems reduce human error and enhance the consistency of inspection results, making them an invaluable tool in industries with high inspection demands.

Data-Driven Insights

Data analytics play a significant role in determining optimal inspection frequency. By analyzing historical inspection data, organizations can identify patterns and trends that inform future inspection schedules. This data-driven approach ensures that inspections are conducted when they are most needed, maximizing their effectiveness.

Case Studies: Frequency in Action

Food Industry

The food industry is a prime example of how inspection frequency can impact results. Frequent inspections are essential to prevent contamination and ensure food safety. The industry relies on a combination of regulatory requirements and internal standards to determine inspection frequency.

Manufacturing Sector

In manufacturing, inspection frequency is critical for maintaining product quality and operational efficiency. By conducting regular inspections, manufacturers can identify defects early and implement corrective measures, reducing waste and enhancing productivity.

Energy Sector

The energy sector, particularly in areas such as wind turbine inspection, utilizes frequency analysis to optimize inspection schedules. This approach is detailed in frequency analysis in wind turbine inspection, where inspections are scheduled based on operational data and environmental conditions.

Conclusion

Understanding how frequency influences inspection results is essential for industry professionals seeking to enhance quality assurance processes. By considering factors such as regulatory requirements, operational risk, and technological advancements, organizations can determine the optimal inspection frequency that ensures safety, quality, and efficiency.

For more insights on inspection frequency, you can visit this external resource for a comprehensive understanding of inspection terms and definitions.

FAQs

Why is inspection frequency important?

Inspection frequency is important because it determines the thoroughness and reliability of the inspection results. It ensures that safety and quality standards are consistently met.

How does technology impact inspection frequency?

Technology impacts inspection frequency by enabling more precise and efficient inspections. Automated systems and data analytics help optimize inspection schedules, ensuring inspections are conducted when most needed.

What are the challenges in determining inspection frequency?

Challenges in determining inspection frequency include balancing cost and quality, adapting to changes in regulations and technology, and ensuring inspections are conducted without compromising operations.

This article contains affiliate links. We may earn a commission at no extra cost to you.