How to bore a cylinder with a milling machine is a technical yet rewarding task every engineer or machinist should master. Today’s topic will walk you through the entire process, ensuring that even the most intricate details are covered.

Understanding the Milling Machine

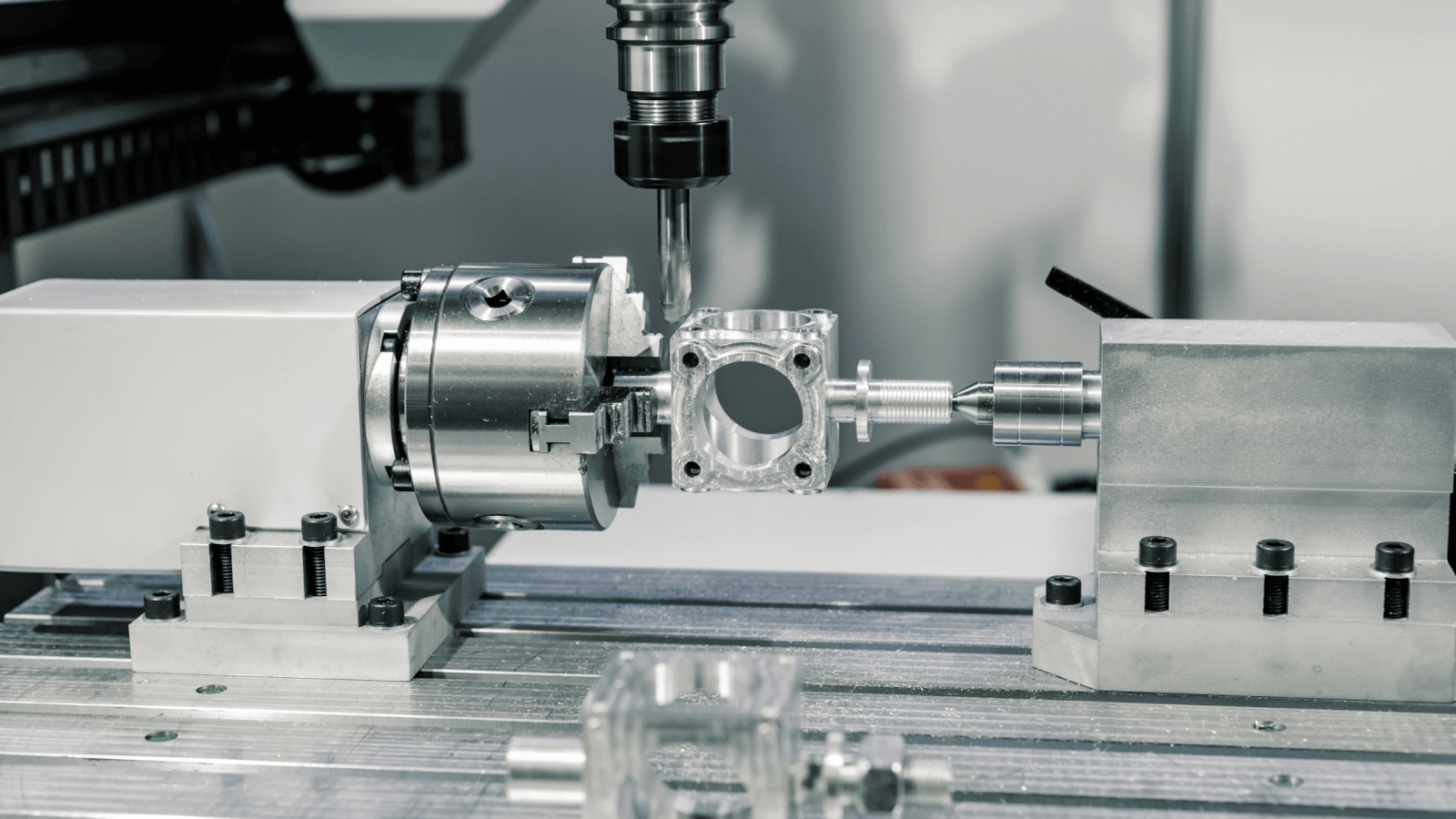

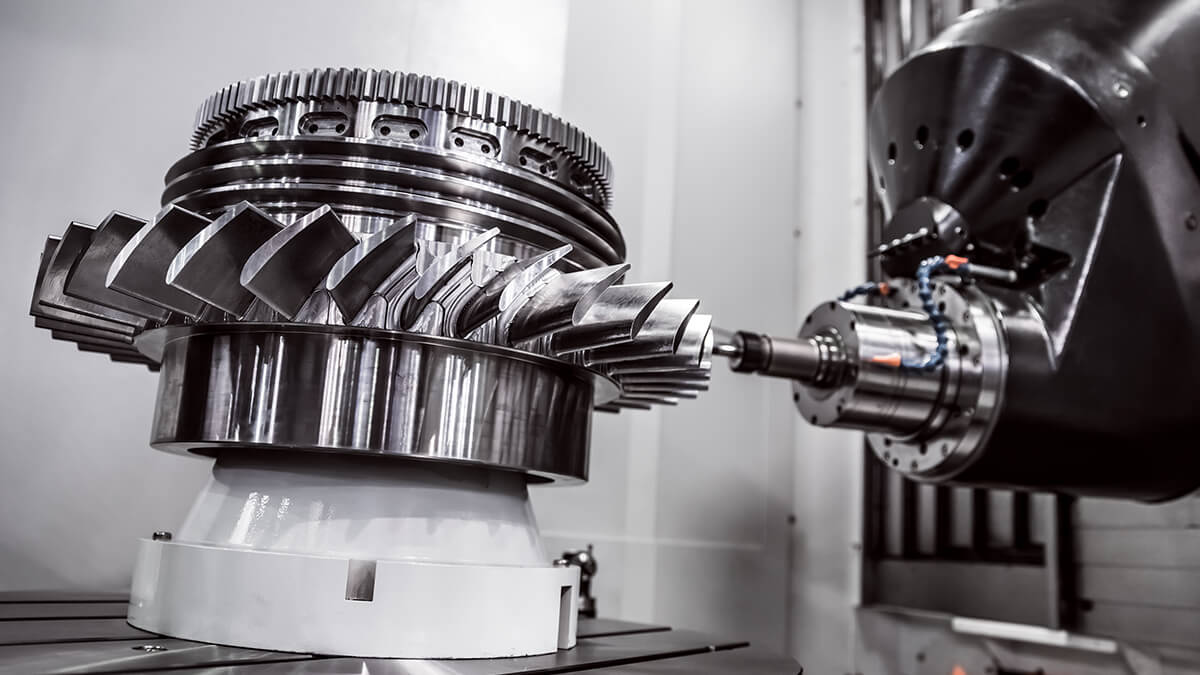

Before diving into the steps on how to bore a cylinder with a milling machine, it’s crucial to understand the milling machine itself. This fundamental tool is used in the metalworking industry for shaping solid materials.

The manual lathe is one of the most essential tools, closely linked to the milling machine. It’s similar in form but offers unique functionalities.

The Basics: What You Need

To begin, gather these essential items:

- Milling machine

- Appropriate boring head and tool holders

- Cylindrical workpiece

- Measurement tools (vernier calipers, micrometers, etc.)

- Cooling and lubrication fluids

Setting Up the Milling Machine

Choosing the Right Milling Machine

Not all milling machines are the same. There are several milling machines, and choosing the right one is vital. You can learn more about the types of milling machines here.

For boring a cylinder, you need a milling machine that can handle the size and hardness of the material.

Workholding Devices

Securing the workpiece is crucial. You can read more about workholding devices in milling machines here.

Step-by-Step Guide on How to Bore a Cylinder with a Milling Machine

1. Preparing the Workpiece

Ensure the workpiece is free of any debris or contaminants. Cleaning it thoroughly is essential for precision.

2. Mounting the Workpiece

Secure the cylinder firmly onto the workholding device. Correct alignment is critical.

3. Setting the Bore Diameter

Input the desired bore diameter into your milling machine’s control panel.

4. Selecting the Right Boring Head

Choose a boring head that fits your milling machine and the intended bore diameter.

5. Adjusting Speed and Feed Rates

The speed and feed rates must be adjusted according to the material. This will ensure a smooth and precise bore.

6. Engaging the Milling Machine

Start the milling machine, allowing the boring head to enter the workpiece gradually. Ensure consistent coolant application.

7. Measuring and Verifying

Once the boring process is complete, use measurement tools to verify the bore diameter and ensure it meets specifications.

Common Challenges and How to Overcome Them

Tool Wear

Boring heads experience wear over time. Regularly inspect your tools and replace them when necessary.

Material Hardness

Harder materials require slower feed rates and more cooling.

Maintenance Tips for Your Milling Machine

To keep your milling machine in top condition, follow these maintenance tips:

- Regularly lubricate moving parts

- Inspect and replace worn components

- Clean the machine after each use

Conclusion

Learning how to bore a cylinder with a milling machine is an invaluable skill. With the right tools and techniques, you can achieve precision and efficiency. Stay informed and practice regularly to master this art.

FAQs

What is the primary tool needed for cylinder boring?

A milling machine equipped with a suitable boring head is necessary.

How do I choose the right boring head?

Consider the material and desired bore diameter when selecting a boring head.

What are the advantages of using a milling machine?

For detailed information about the advantages of using CNC machines over traditional lathes, click here.

Where can I learn more about machining?

To further your knowledge in machining, you can read this article.