When it comes to machining, one of the frequent tasks involves cutting a keyway on a milling machine. This process is pivotal in creating mechanical components that require a slot or keyway, aiding in proper function and interlocking. Industry QA professionals often face challenges in nailing down this task efficiently. Well, it’s here the answer to your queries with some big, approved technology tips!

Introduction to Keyway Cutting

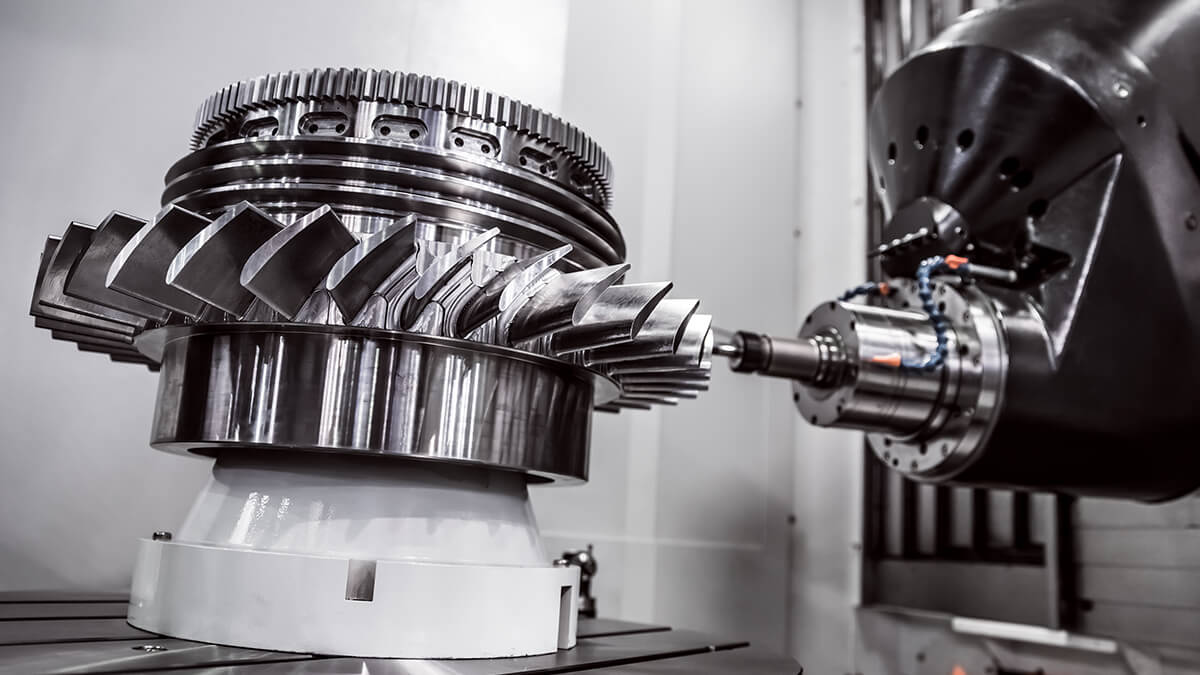

Before diving into the steps, it’s essential to understand the significance of keyway cutting. A keyway is a slot or a groove which is an integral part of many mechanical components. They ensure the proper functioning of gears, hardware, pulleys, and shafts in various machinery. Now, lets talk about how to cut a keyway on a milling machine.

Why Keyway Cutting is Crucial

Proper keyway cutting helps in distributing torque and aligning machine parts effectively. A poorly cut keyway can lead to misalignment, wear and tear, and in some cases, catastrophic failure. Having the know-how to cut a precise keyway is an invaluable skill in the machining world.

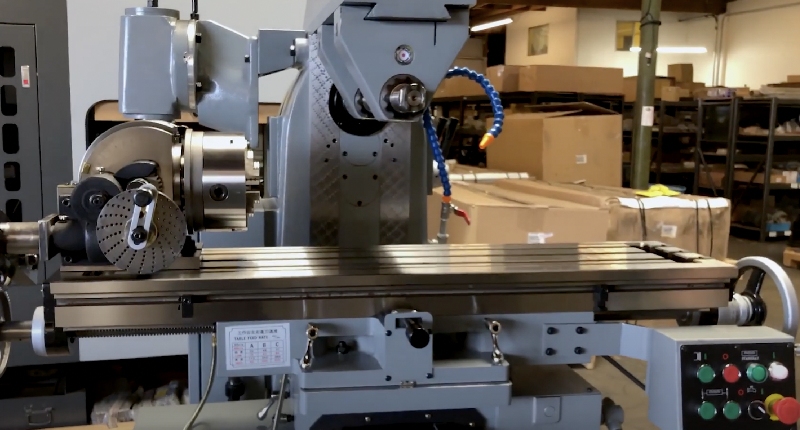

Milling Machines: An Overview

Understanding your milling machine is the first step. Milling machines come in various types, each with its unique features and applications. The standard milling machine types include vertical, horizontal, and universal types. Knowing your machine’s capabilities will help you in achieving a precise keyway.

Setting Up Your Milling Machine

The initial setup process is paramount. Begin by ensuring your milling machine is calibrated correctly. Follow these steps:

- Check the machines alignment Both the spindle and the worktable should be aligned accurately.

- Secure the workpiece Ensure the workpiece is firmly clamped to avoid any movement during the cutting process.

- Select the appropriate cutting tool Use an end mill or a broach suitable for the keyways specifications.

Choosing the Right Tool

Your tool choice is crucial for a clean cut. Depending on your material and keyway specifications, you might use an end mill or a broach. Remember, using a high-speed steel (HSS) or carbide tool can result in better precision and longer tool life.

End Mills and Broaches

End mills are excellent for cutting keyways directly into the workpiece, while broaches are primarily used for creating keyways in round holes. Choose accordingly based on your project requirements.

Step-by-Step Guide on Cutting a Keyway

Step 1: Planning and Measuring

Start by planning your cut. Measure and mark the location of the keyway accurately on the workpiece.

Step 2: Positioning the Workpiece

Attach the workpiece to the milling machines worktable using clamps or a vice. Ensure it is immovable.

Step 3: Setting the Cutting Depth

Adjust the milling machine to the desired cutting depth. This is usually done by setting the spindle or cutter head.

Step 4: Cutting the Keyway

Proceed to cut the keyway by moving the cutting tool into the workpiece. Use steady, consistent feed rates to ensure a smooth cut.

Step 5: Finishing Touches

After cutting, inspect the keyway for precision. Use a file to remove any burrs or rough edges.

Common Mistakes and How to Avoid Them

Even with detailed preparation, mistakes can happen. Here are some common errors and tips to avoid them:

- Improper tool selection: Choose tools based on material and keyway specifications.

- Inadequate clamping: Ensure the workpiece is secured properly to avoid any movement.

- Poor measurement: Always double-check measurements before making the cut.

Maintenance of Milling Machines

Regular maintenance of your milling machine ensures longevity and precision. Conduct frequent inspections, clean the machine, and lubricate moving parts regularly.

Advanced Techniques for Precision

For industry QA professionals, achieving top-notch precision is crucial. Consider using CNC milling machines for incredibly precise keyway cuts. You can read more about CNC machine advantages here.

FAQs

- What is the best tool for cutting keyways? The choice depends on the material and dimensions, but end mills and broaches are common choices.

- Can you cut a keyway using a CNC machine? Yes, CNC machines are highly precise and suitable for cutting keyways.

- How often should I maintain my milling machine? Regular maintenance should be conducted periodically to ensure optimal performance.

Further Reading

For more information on milling machine types, visit The Engineering Choice.

Additionally, dive into the basics of manual lathes here and learn about workholding devices for milling machines here.

By following this comprehensive guide, youll master how to cut a keyway on a milling machine, bringing immense value to your machining tasks and enhancing overall efficiency in industrial applications.