In the world of industrial quality assurance, measuring rotational speed or RPM (Revolutions Per Minute) is a fundamental task. However, what if your tachometer is not available? This is where knowing how to measure RPM without a tachometer becomes vital. This guide delves into various innovative methods for determining the RPM without traditional means, ensuring the task is performed efficiently and accurately.

Understanding RPM: Why It’s Important

Before delving into how to measure RPM without a tachometer, its important to understand why RPM is crucial. Essentially, RPM is a measurement of how many complete turns or revolutions an object makes in a minute. Its widely used in industries like automotive, manufacturing, and electronics to gauge the performance and stability of rotating parts.

Challenges of Measuring RPM Without a Tachometer

Not having a tachometer can pose several challenges, particularly for industry QA professionals who rely on precise readings. The biggest hurdle is achieving an accurate and reliable measurement. Here, we will outline various methods that experts use to overcome these challenges.

Method 1: Using a Strobe Light

A strobe light can be a powerful tool for determining RPM. By matching the flash frequency of the strobe light with the rotational speed of the object, you can discern its RPM. This method is precise and widely used in different sectors of industry. For a deeper understanding of stroboscopic event detection, you can refer to this high-speed event detection.

Steps to Measure RPM Using Strobe Light

- Firstly, mark a point on the rotating object for reference.

- Set up the strobe light, ensuring it’s oriented correctly towards the marker.

- Adjust the flash frequency until the marker appears stationary.

- The flash frequency at this point is equivalent to the RPM of the object.

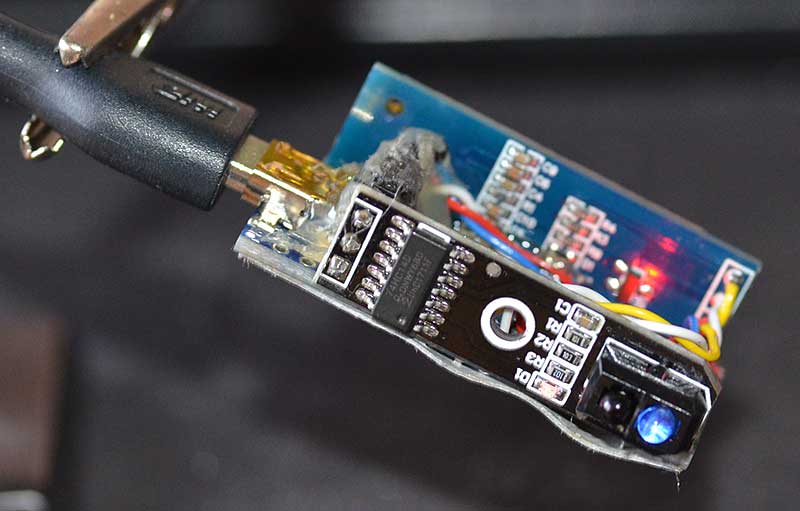

Method 2: Using a Frequency Counter

Another practical approach to measure RPM is by using a frequency counter. This device measures the frequency of electrical pulses and can be applied effectively to rotating objects equipped with a magnetic or optical sensor.

Steps to Measure RPM Using Frequency Counter

- Attach the sensor to the rotating part.

- Connect the sensor to the frequency counter.

- Record the frequency readings.

- Convert the frequency to RPM using the formula: RPM = (Frequency * 60) / Number of sensor pulses per revolution.

Method 3: Measuring with an Oscilloscope

An oscilloscope can provide a visual representation of the rotational speed. It captures and displays the waveforms of the signals generated by the rotating object, which can be analyzed to determine the RPM.

Steps to Measure RPM Using Oscilloscope

- Connect the signal source from the rotating part to the oscilloscope input.

- Set the oscilloscope to the appropriate mode to display the waveform.

- Analyze the waveform frequency, and then convert this frequency to RPM.

Method 4: Mechanical Tachometer Alternatives

Despite not having a digital tachometer, mechanical alternatives like friction wheels or revolution counters can help measure RPM. These tools offer simplicity, albeit at potential trade-offs in terms of precision.

Using a Friction Wheel

- Place the wheel in contact with the rotating part.

- Ensure the wheel’s movement is transferred to a measured dial.

- Record the readings from the dial to calculate RPM.

Using a Revolution Counter

- Manually count the number of revolutions within a specific time frame (e.g., 30 seconds).

- Multiply the number of counted revolutions to get RPM.

Method 5: The Paper Disk Method

This method involves attaching a paper disk with marked intervals to the rotating part. By visually counting the marks as they pass a fixed point, the RPM can be determined through simple calculations.

Steps to Measure RPM Using Paper Disk

- Attach a paper disk with evenly spaced markings to the rotating part.

- Count the number of marks passing a fixed point in a specified time.

- Divide the number of marks by the time to find RPM.

Benefits of Non-Tachometer RPM Measurement Methods

These methods offer significant benefits, especially in situations where a tachometer is unavailable or impractical. They are versatile, often more accessible, and can be performed with various available tools in industrial settings.

Accessibility

Tools like strobe lights and oscilloscopes are often readily available in many industrial environments, making these methods highly accessible.

Cost-Effectiveness

Most alternative methods, especially the mechanical and visual ones, are more cost-effective compared to digital tachometers.

Industrial Applications

These RPM measuring methods have wide-ranging applications. For instance, the semiconductor manufacturing industry often uses high-speed visual techniques to ensure the performance of rotating machinery. Learn more about these industrial applications through wafer polishing inspections.

Safety Considerations

While engaging in physical measurement techniques, it’s paramount to prioritize safety. Always ensure that rotating parts are securely attached and that measurement tools are used correctly to avoid accidents.

Further Reading and Resources

For a more in-depth understanding of tachometers and their principles, refer to this comprehensive guide. To explore the latest technological advancements in rotational speed measurement, consider reading industry publications or joining professional forums.

Frequently Asked Questions (FAQ)

Q: What is the most accurate method to measure RPM without a tachometer?

A: Using a strobe light is often the most accurate method, as it precisely matches the frequency of the rotation.

Q: Are these methods applicable for measuring RPM in high-speed applications?

A: Yes, methods like strobe light and oscilloscopes are particularly suitable for high-speed applications.

Q: How do these methods compare in terms of complexity?

A: While tools like oscilloscopes and frequency counters require technical knowledge, mechanical methods like friction wheels are simpler but less precise.