CNC milling machines revolutionize the manufacturing industry by offering precision and efficiency. These machines are pivotal in the production of complex parts and components. In this guide, we will delve into how to use a CNC milling machine, ensuring that you, whether a seasoned professional or a curious enthusiast, gain a comprehensive understanding of this terrific technology.

What is a CNC Milling Machine?

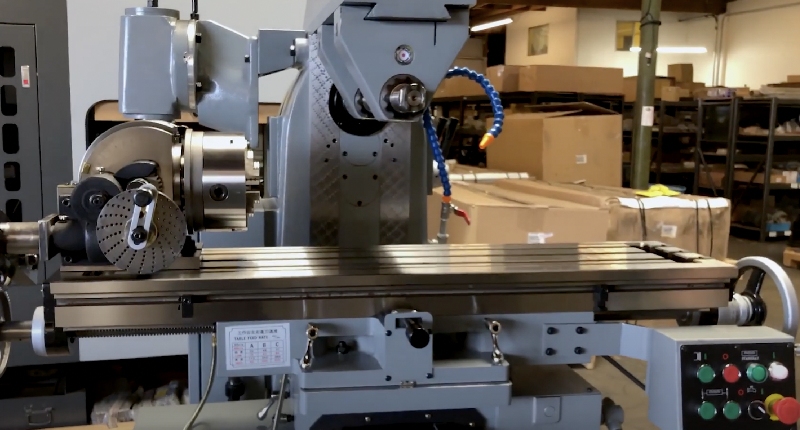

A CNC (Computer Numerical Control) milling machine is a highly automated piece of equipment that is used for shaping and machining materials. It operates using computer programming, enabling precise control over intricate designs and patterns.

Components of a CNC Milling Machine

- Frame

- Spindle

- Control Panel

- Tool Holder

- Working Table

Setting Up the Machine

Before you start operating the CNC milling machine, proper setup is crucial. This includes setting up the machine tool, loading the correct software, and ensuring a stable work environment. You can find detailed guidelines on proper setup and maintenance here.

Understanding CNC Programming

Programming a CNC milling machine involves creating a set of instructions that the machine follows to produce the desired output. This is usually done using G-code, a language that tells the CNC machine how to move its components.

Basic G-Code Commands

- G00 – Rapid move

- G01 – Linear interpolation

- G02/G03 – Circular interpolation

- G17/G18/G19 – Plane selection

Loading and Unloading Tools

Proper tool management is essential in CNC milling. Tools should be loaded accurately and securely to avoid any mishaps during the operation. For more information on the basics of tools and manual lathes, you can refer here.

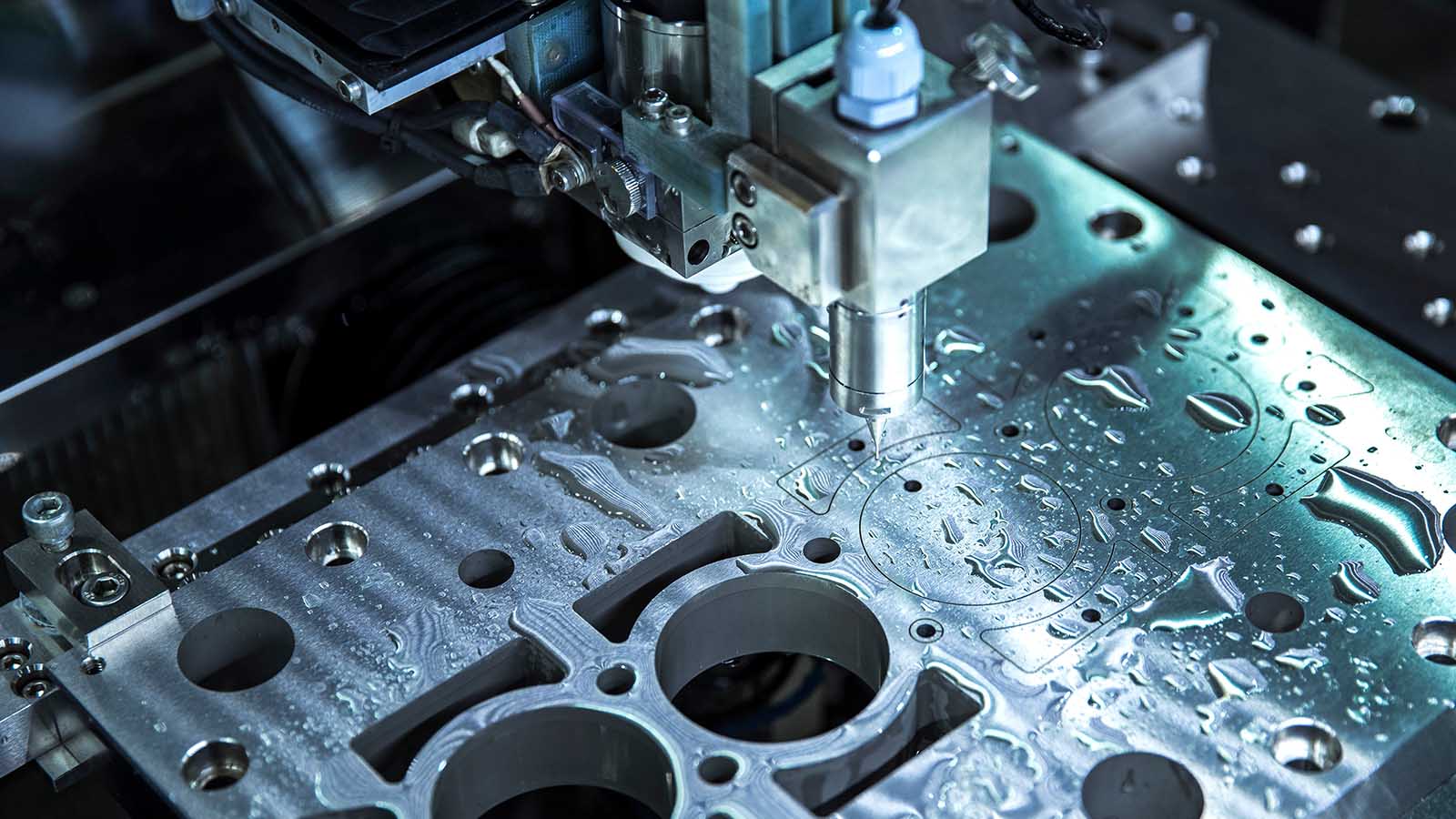

Running the Machine

Once everything is set and programmed, you can proceed to run the CNC milling machine. This involves close monitoring to ensure that the process is smooth and accurate.

Quality Control

After the machining process, its vital to perform rigorous quality control checks to ensure that the final product meets the required specifications. This is where industry QA professionals play a critical role.

Safety Precautions

Operating a CNC milling machine can be dangerous if proper safety measures are not taken. Always wear protective gear and follow the machine’s safety guidelines to avoid accidents.

Common Safety Tips

- Wear safety goggles

- Keep hands away from the moving parts

- Ensure proper ventilation

- Follow the emergency stop procedures

Advantages of Using CNC Milling Machines

CNC milling machines offer several benefits over traditional machining methods, making them a tremendous asset in modern manufacturing. You can learn more about the advantages of CNC machines here.

Common Issues and Troubleshooting

Even with sophisticated technology, CNC milling machines can face operational issues. Knowing how to troubleshoot common problems is essential for maintaining efficiency and reducing downtime.

Frequent Problems

- Tool Breakage

- Inaccurate Cuts

- Software Glitches

- Overheating

Regular Maintenance

Maintaining your CNC milling machine is crucial for its longevity and optimal performance. Regular inspections and timely repairs can save you from costly replacements and prolonged downtimes.

Maintenance Tips

- Keep the machine clean

- Regularly check for wear and tear

- Lubricate moving parts

- Calibrate the machine periodically

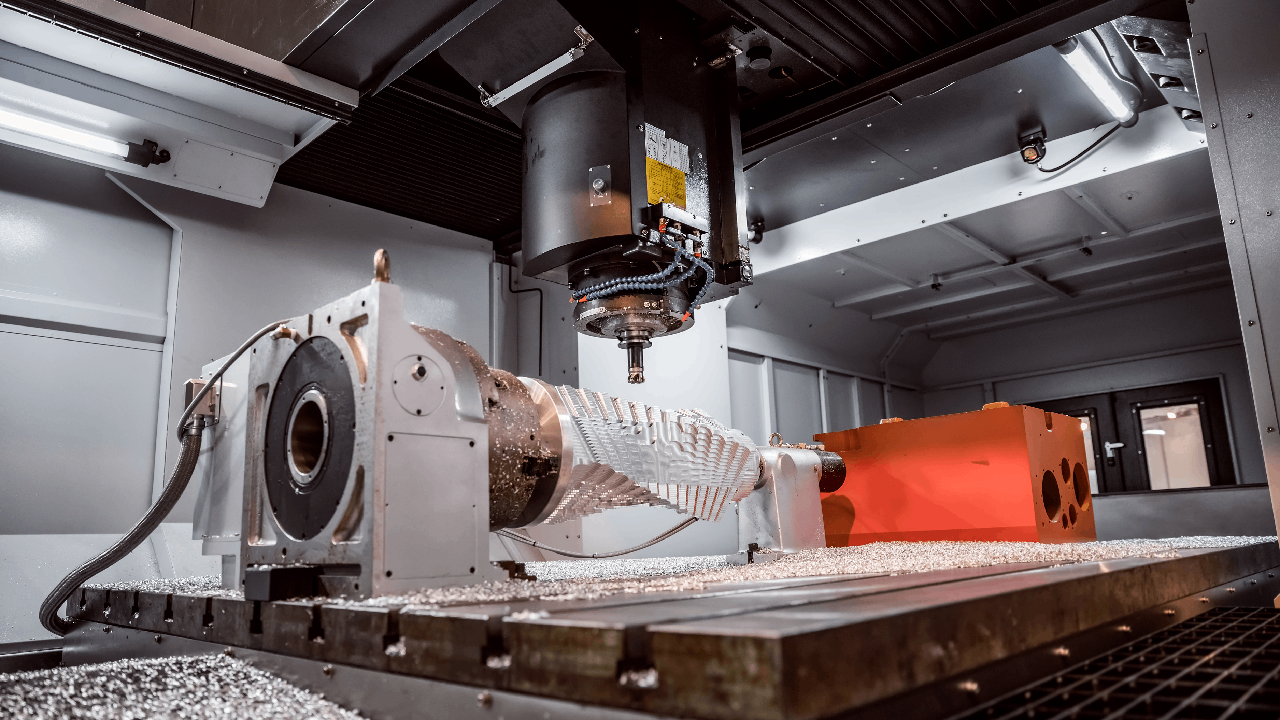

Innovations and Future Trends

The field of CNC milling is continuously evolving with advancements in technology. Emerging trends include automation, AI integration, and more efficient and eco-friendly processes.

FAQs

What materials can be machined using a CNC milling machine?

CNC milling machines can machine a wide range of materials, including metals, plastics, and wood.

Do I need special training to operate a CNC milling machine?

Yes, proper training and understanding of CNC programming are essential to operate the machine safely and efficiently.

How do I maintain a CNC milling machine?

Regular maintenance includes cleaning, lubrication, calibration, and timely inspections.

Conclusion

Mastering how to use a CNC milling machine can significantly enhance your production capabilities and open doors to greater innovation in manufacturing. Embrace this terrific technology and take your skills to the next level!