An inductive tachometer is a device used to measure the speed of rotating objects such as engines or motors. Knowing how to use an inductive tachometer can greatly benefit Industry QA professionals by providing accurate data on rotational speeds.

Understanding the Basics

The primary function of an inductive tachometer is to detect the magnetic field generated by rotating objects. This device is vital for engines and machinery in various industries such as automotive, aerospace, and manufacturing.

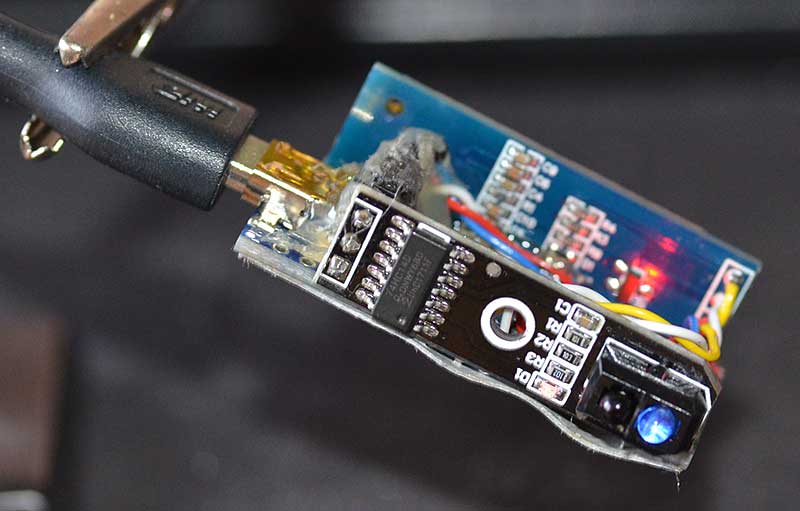

Parts of an Inductive Tachometer

Sensor

The sensor detects the magnetic field created by the rotating object.

Display

The display shows the speed of rotation.

Power Source

Most inductive tachometers operate on batteries.

How to Set Up an Inductive Tachometer

Step 1: Gather Your Tools

Ensure you have the tachometer, sensor, and necessary batteries.

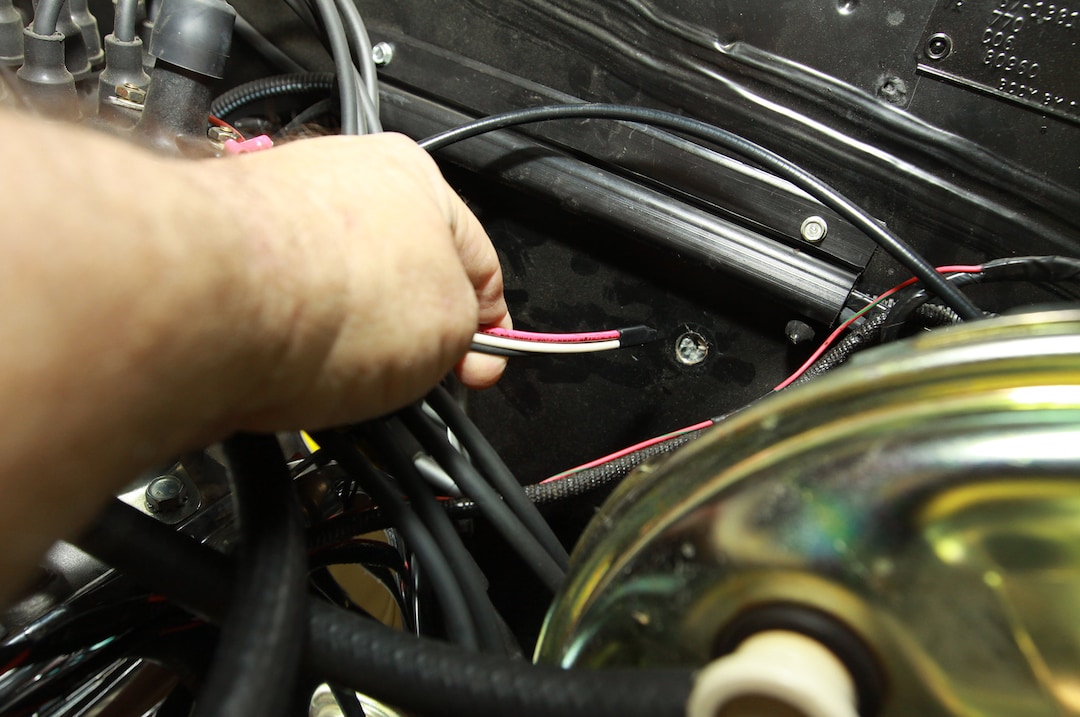

Step 2: Connect the Sensor

Attach the sensor close to the rotating object.

Step 3: Power On

Turn on the device to start measuring.

How to Calibrate an Inductive Tachometer

Initial Setup

Follow the manufacturer’s instructions for the initial setup.

Calibration Check

Perform a calibration check regularly to ensure the accuracy of the device.

Common Uses of an Inductive Tachometer

Inductive tachometers are widely used in:

- Automotive industry for engine speed measurement.

- Aerospace for monitoring aircraft engine speeds.

- Manufacturing for machine speed regulation.

Benefits of Using an Inductive Tachometer

Some benefits include:

- High accuracy.

- Non-invasive measurement.

- Reliability.

Troubleshooting Common Issues

Sensor Problems

Check the sensor if the device is not giving accurate readings.

Battery Issues

Replace the batteries if the device is not powering on.

Maintaining Your Inductive Tachometer

Regular Cleaning

Keep the sensor and display clean for accurate readings.

Periodic Calibration

Calibrate the device periodically.

Advanced Tips for Industry QA Professionals

For Industry QA professionals, here are some advanced tips:

- Integrate the tachometer with other QA tools.

- Use software for data logging and analysis.

The Future of Inductive Tachometers

As technology advances, so do the capabilities of inductive tachometers. Future models may include wireless data transmission and enhanced accuracy, making them even more invaluable to Industry QA professionals.

Conclusion

Inductive tachometers are essential tools in various industries for measuring the speed of rotating objects. By understanding how to use an inductive tachometer properly, Industry QA professionals can ensure accurate and reliable data, leading to improved quality control and operational efficiency.

FAQs

1. What industries benefit most from inductive tachometers?

Industries such as automotive, aerospace, and manufacturing benefit the most.

2. How often should I calibrate my inductive tachometer?

It’s best to calibrate before each major project or as recommended by the manufacturer.

3. Can an inductive tachometer measure the speed of any rotating object?

As long as the object generates a magnetic field, the device can measure its speed.

Learn more about types of tachometers and their uses.

For in-depth information, visit Science Direct.