What is tachometer in aircraft? A tachometer is a crucial instrument found in aircraft that provides essential data to pilots. Ensuring optimal performance, it measures the rotational speed of the engine’s crankshaft, giving pilots real-time information about the engine’s RPM (rotations per minute). Understanding this instrument is paramount for both safety and efficiency during flights.

The Basics of Tachometer

Tachometers play a pivotal role in monitoring engine performance. They are designed to provide immediate feedback, helping pilots maintain the desired engine parameters. This instrument’s importance cannot be understated as it directly affects the aircraft’s performance and safety.

The Importance of Tachometer

Tachometers are critical in detecting engine malfunctions early. By closely monitoring the RPM, pilots can ensure the engine operates within safe limits, preventing over-speeding or under-speeding.

Types of Tachometers in Aircraft

Mechanical Tachometers

Mechanical tachometers, though less common today, have been widely used in older aircraft. They function by utilizing a flexible, rotating cable driven by the engine. Learn more.

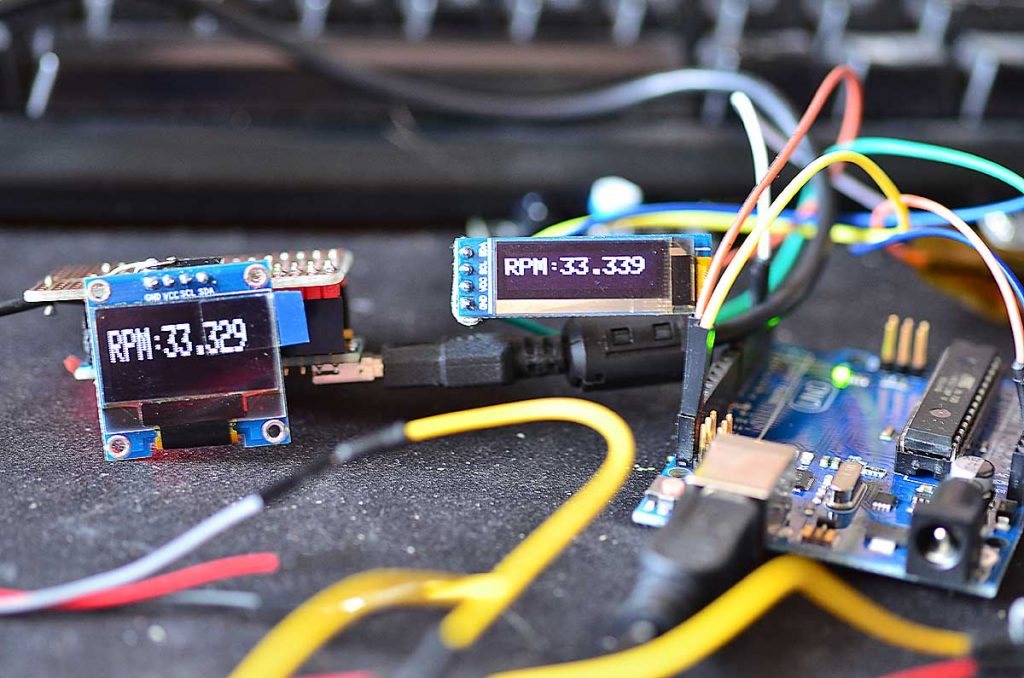

Digital Tachometers

Modern aircraft are equipped with digital tachometers. These advanced devices use electronic signals to measure RPM, providing more precise and reliable data.

How Does a Tachometer Work?

A tachometer operates by measuring the time interval between engine pulses. The data collected is then converted into a readable RPM format displayed on the cockpit instrument panel.

The Working Principle

Tachometers use magnetic sensors or optical encoders to generate signals. These signals correspond to the rotational speed of the engine, which is then processed and displayed to the pilot.

Installation and Maintenance of Tachometers

Installation Process

Installing a tachometer requires precision. Proper calibration is crucial to ensure accurate readings. It involves mounting the sensor near the engine’s rotating parts and connecting it to the cockpit display unit.

Maintenance Tips

Regular maintenance of tachometers is necessary to ensure their accuracy. This includes inspecting the sensors, checking for loose connections, and recalibrating the instrument as needed.

Advantages of Using Tachometers in Aircraft

Enhanced Safety

Tachometers play a vital role in maintaining engine health, thereby enhancing flight safety. They provide real-time data, allowing pilots to make informed decisions.

Improved Performance

By monitoring the engine’s RPM, tachometers help in optimizing fuel consumption and maximizing performance.

Challenges in Using Tachometers

Technical Issues

Although rare, tachometers can face technical issues such as signal interference or calibration errors. Regular maintenance can mitigate these problems.

Environmental Factors

Extreme environmental conditions can impact the accuracy of tachometers. It’s imperative to ensure they are designed to withstand such conditions.

Future Trends in Tachometer Technology

Integration with Advanced Avionics

The future of tachometer technology lies in integrating them with advanced avionics systems, ensuring seamless data flow and enhancing overall flight safety and efficiency.

Adoption of AI and ML

Artificial Intelligence and Machine Learning are set to revolutionize tachometer technology, providing more predictive maintenance capabilities and enhancing reliability.

For detailed insights, you can refer to this comprehensive guide on how tachometers work.

Expert Opinions on Tachometers

Industry experts agree that tachometers are indispensable in modern aviation. Their role in ensuring engine health and flight safety cannot be overstated.

FAQs

What is a tachometer used for in aircraft?

A tachometer in an aircraft measures the engine’s RPM, providing crucial information for maintaining optimal engine performance and safety.

How often should tachometers be calibrated?

Tachometers should be calibrated during every maintenance check or whenever a discrepancy in readings is noticed.

Can digital tachometers fail?

Though uncommon, digital tachometers can fail due to technical issues. Regular checks and maintenance can help prevent such occurrences.

For more practical insights, you can visit our pages on Event Detection, Paint Inspection, and Genetic Analysis.