When it comes to precision drilling in the manufacturing and industrial sectors, selecting the right equipment is crucial. A common question that arises is, what type of drill press chuck should be used with a straight shank twist drill? Understanding this will ensure not only the efficiency of your operations but also the quality and accuracy of the work produced.

Understanding Drill Press Chucks

Drill press chucks are an integral component of any drilling machine. They are designed to hold the drill bit firmly while it is being driven into the material. Various types of chucks are available, each suited to different kinds of drill bits and applications.

Types of Drill Press Chucks

There are several varieties of drill press chucks that you can opt for:

- Keyed Chucks

- Keyless Chucks

- Precision Chucks

- Jacobs Chucks

Important Words in Double Quotes

In understanding the types of chucks, it’s crucial to keep some important words in mind: Keyed Chucks, Keyless Chucks, Precision Chucks, and Jacobs Chucks. These terms will be frequently used throughout this article.

Why Use a Straight Shank Twist Drill?

A straight shank twist drill is a versatile tool used in various drilling applications. Its straight shank allows it to be held securely in the chuck, providing stability and precision during drilling.

Advantages of Straight Shank Twist Drills

- They provide excellent stability during drilling

- They are versatile and compatible with different chucks

- They ensure high precision and accuracy

How to Choose the Right Chuck

Choosing the right chuck for your straight shank twist drill depends on various factors such as the type of material you are drilling, the drilling speed, and the precision required. Here, we’ll explore these factors in detail.

Keyed vs. Keyless Chucks

Both keyed and keyless chucks have their pros and cons. Keyed chucks provide a more secure grip on the drill bit, ensuring it does not slip during drilling. On the other hand, keyless chucks offer convenience, allowing for quick and easy bit changes without the need for a key.

Industry Applications

In industrial settings, the choice of a drill press chuck can significantly impact productivity and accuracy. For example, in semiconductor manufacturing, precision is paramount, and therefore, the right chuck is critical.

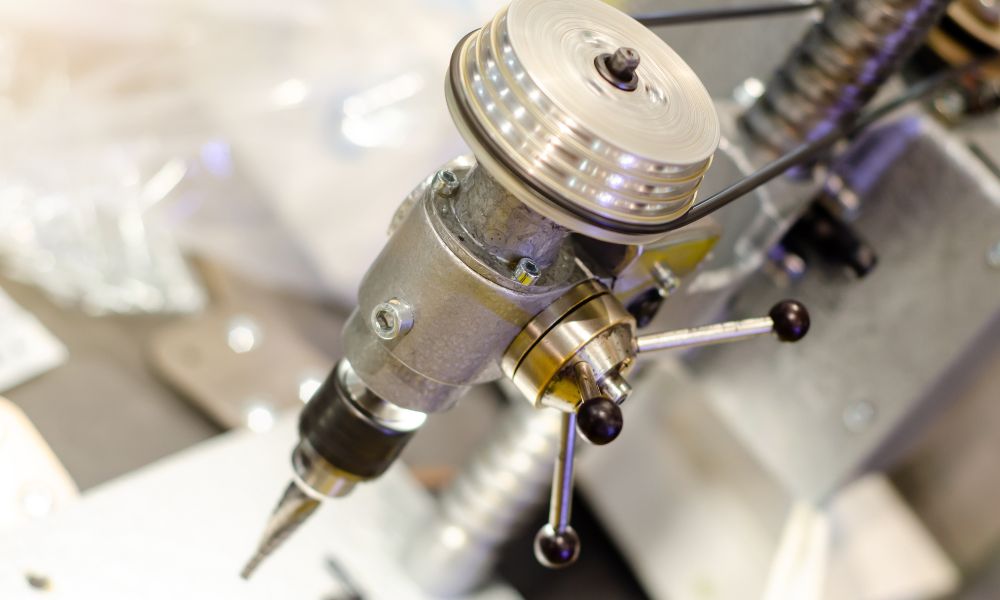

Choosing Precision Chucks

Precision chucks are often used in high-precision applications where even the slightest movement of the drill bit can cause errors. These chucks provide a firm grip on the drill bit, ensuring optimal accuracy.

Jacobs Chucks: A Popular Choice

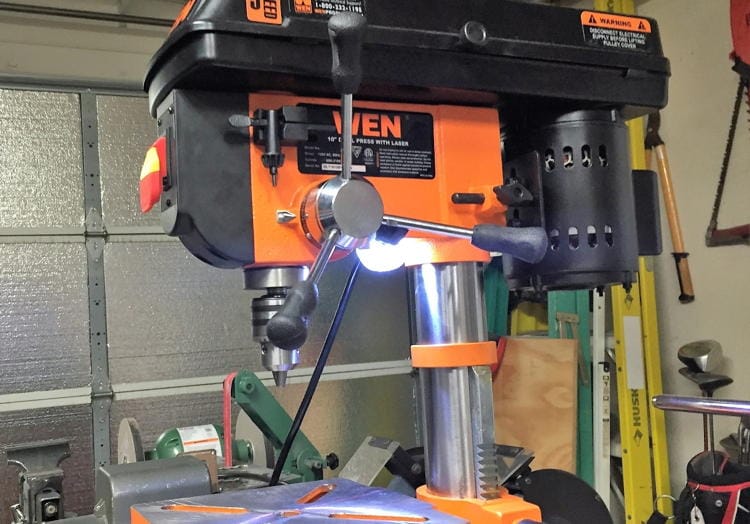

Jacobs chucks are among the most popular types of drill press chucks. Known for their robustness and reliability, they are often used in both industrial and home workshop settings. Whether you are working on a high-speed paint and coating application inspection or any other intricate drilling task, Jacobs chucks could be a suitable choice.

Maintenance of Drill Press Chucks

Regular maintenance is essential to ensure the longevity and optimal performance of your drill press chucks. Here are some tips for maintaining your chucks:

- Clean them regularly to remove debris

- Lubricate moving parts to prevent rust

- Inspect for wear and tear, replacing parts as necessary

Safety Considerations

When using any type of drill press chuck, safety should always be a priority. Ensure that the drill bit is securely fastened in the chuck and that you are using the appropriate personal protective equipment (PPE).

External Safety Resources

For more detailed guidance on safety, you can refer to OSHA’s drill press safety guidelines.

Choosing the Correct Chuck for Specific Materials

The type of material you are working with can also influence your choice of chuck. Here are some examples:

- For soft materials like wood, a keyless chuck may suffice

- For harder materials like metal, a keyed or precision chuck is recommended

Troubleshooting Common Problems

Even with the right equipment, you may face some challenges. Heres how to troubleshoot common issues:

- Drill Bit Slippage: Ensure the bit is tightly secured in the chuck

- Inconsistent Drilling: Check for wear and tear on the chuck or drill bit

- Vibrations: Ensure the drill bit and chuck are properly aligned

Future Trends in Drill Press Technology

As technology advances, we can expect to see significant improvements in drill press chucks. Innovations like automatic tightening chucks and enhanced precision models are just some of the exciting developments on the horizon.

Drill Press Technology and Quality Assurance

Quality assurance professionals will benefit from these technological advancements as they provide better control and accuracy, essential for high-quality outputs. For instance, during high-speed genetic analysis and sequencing monitoring, precision is vital.

Conclusion

In conclusion, understanding what type of drill press chuck should be used with a straight shank twist drill is crucial for achieving optimal results in your drilling operations. Whether you choose a keyed, keyless, precision, or Jacobs chuck, ensure it meets your specific needs and application requirements. Regular maintenance and adherence to safety guidelines will ensure your equipment remains in top condition.

FAQ Section

What are the main types of drill press chucks?

The main types include keyed chucks, keyless chucks, precision chucks, and Jacobs chucks.

Why is it important to choose the right chuck?

Choosing the right chuck ensures stability, precision, and efficiency in your drilling operations.

What safety precautions should be taken when using a drill press chuck?

Ensure the drill bit is securely fastened and use appropriate PPE. Regular maintenance and adherence to safety guidelines are also crucial.