The manufacturing sector is undergoing a significant transformation as digital technologies become central to operations. Understanding factory digitalization is essential for businesses aiming to stay competitive, improve efficiency, and adapt to rapidly changing market demands. This guide explores the core concepts, benefits, and practical steps for manufacturers looking to embrace digital transformation in their facilities.

As digital tools and connected systems become more prevalent, manufacturers are rethinking traditional processes. From real-time data collection to automated decision-making, digitalization is reshaping how factories operate. For those interested in related advancements, the introduction to factory edge computing provides valuable insights into how edge technologies support this shift.

What Is Digitalization in Manufacturing?

Digitalization in the manufacturing context refers to integrating digital technologies into all aspects of factory operations. This includes the use of sensors, industrial IoT devices, cloud computing, and advanced analytics to collect, process, and act on data from machines, production lines, and supply chains. The goal is to create a connected, intelligent environment where information flows seamlessly and enables smarter decisions.

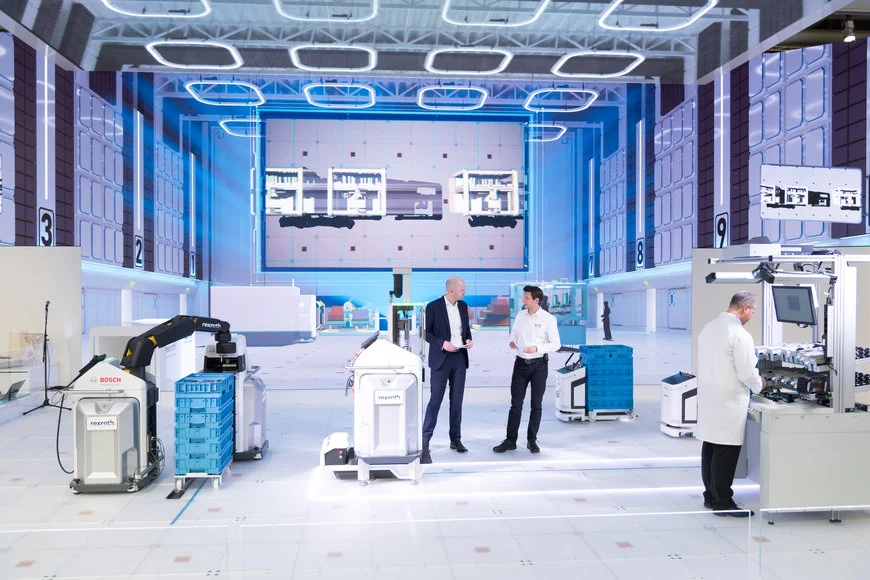

Unlike simple automation, which focuses on replacing manual tasks with machines, digitalization involves a holistic approach. It connects equipment, people, and processes, allowing for real-time monitoring, predictive maintenance, and adaptive production planning. This shift is sometimes called the move toward the “smart factory.”

Key Technologies Powering the Digital Factory

Several core technologies drive the digital transformation of manufacturing facilities. These innovations work together to create a more responsive, efficient, and data-driven environment:

- Industrial Internet of Things (IIoT): Networks of sensors and devices that collect and transmit data from machines and systems.

- Cloud Computing: Centralized platforms for storing, analyzing, and sharing data across the organization. For more on this, see how cloud computing helps factories.

- Artificial Intelligence (AI) and Machine Learning: Algorithms that analyze data to optimize production, predict failures, and automate quality control. Explore how machine learning optimizes production for deeper insights.

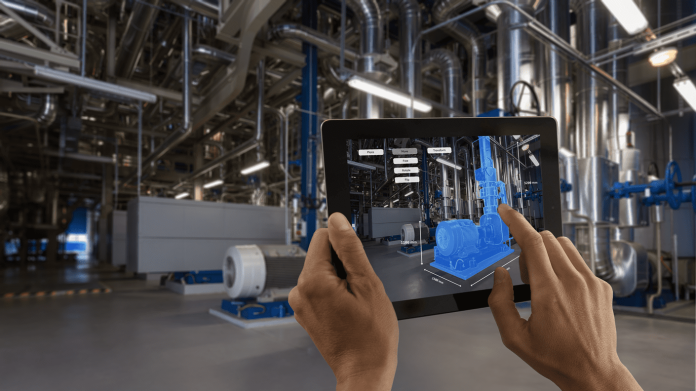

- Digital Twins: Virtual replicas of physical assets or processes used for simulation, monitoring, and optimization.

- Edge Computing: Processing data closer to the source for faster insights and reduced latency.

- Cybersecurity Solutions: Protecting digital assets and ensuring safe operations, as discussed in factory cybersecurity best practices.

Benefits of Embracing Smart Manufacturing

Adopting digital solutions in manufacturing brings a range of advantages. Companies that invest in these technologies often see improvements in productivity, cost savings, and product quality. Some of the most notable benefits include:

- Increased Efficiency: Automated data collection and analysis streamline processes, reducing downtime and waste.

- Enhanced Flexibility: Digital systems enable rapid adjustments to production schedules and product designs.

- Improved Quality: Real-time monitoring and predictive analytics help identify defects early and maintain high standards.

- Cost Reduction: Optimized resource use and predictive maintenance lower operational expenses.

- Better Decision-Making: Access to comprehensive, up-to-date data supports informed choices at every level of the organization.

- Stronger Supply Chains: Digital connectivity improves coordination with suppliers and customers, enhancing responsiveness.

For a detailed overview of how these benefits play out in practice, the article exploring smart factory concepts and their advantages offers further reading.

Steps to Start the Digital Transformation Journey

Moving toward a digital-first factory environment involves careful planning and a phased approach. Here are some practical steps manufacturers can take to begin their transformation:

- Assess Current Capabilities: Evaluate existing equipment, IT infrastructure, and workforce skills to identify gaps and opportunities.

- Set Clear Objectives: Define what you want to achieve—such as reducing downtime, increasing throughput, or improving traceability.

- Prioritize Use Cases: Focus on areas where digitalization will deliver the greatest impact, such as predictive maintenance or automated quality checks.

- Invest in Scalable Technologies: Choose solutions that can grow with your business and integrate with other systems.

- Train and Engage Employees: Provide training and involve staff early to ensure smooth adoption and maximize value.

- Monitor Progress and Iterate: Use data and feedback to refine processes and expand digital initiatives over time.

Challenges and Considerations in Digital Factory Adoption

While the advantages are clear, transitioning to a digital manufacturing environment is not without obstacles. Common challenges include:

- Legacy Systems: Integrating older machines and software with new digital platforms can be complex.

- Cybersecurity Risks: Increased connectivity exposes factories to potential cyber threats, making robust security measures essential.

- Change Management: Employees may be resistant to new technologies or processes, requiring effective communication and training.

- Data Silos: Disconnected systems can limit the value of collected data, emphasizing the need for interoperability.

- Initial Investment: Upfront costs for hardware, software, and training can be significant, though long-term savings often justify the expense.

How Digitalization Is Shaping the Future of Manufacturing

As more manufacturers embrace digital transformation, the industry is seeing a shift toward greater agility, customization, and sustainability. Factories are becoming more adaptive, able to respond quickly to changes in demand or supply chain disruptions. Data-driven insights are enabling predictive maintenance, reducing unplanned downtime, and supporting continuous improvement.

The evolution toward connected, intelligent operations is also opening the door to new business models, such as servitization and mass customization. Companies that invest in digital capabilities today are positioning themselves for long-term success in a rapidly changing market.

Frequently Asked Questions

What is the difference between automation and digitalization in manufacturing?

Automation focuses on using machines or software to perform specific tasks with minimal human intervention. Digitalization, on the other hand, involves integrating digital technologies across all aspects of factory operations, connecting systems, people, and processes for smarter decision-making and greater flexibility.

How can small and medium-sized manufacturers start their digital transformation?

Smaller manufacturers can begin by identifying high-impact areas, such as equipment monitoring or inventory management, and implementing scalable digital solutions. Starting with pilot projects and gradually expanding digital initiatives helps manage costs and build internal expertise.

What are the main risks associated with digitalizing a factory?

Key risks include cybersecurity threats, integration challenges with legacy systems, and potential resistance from employees. Addressing these risks requires a comprehensive strategy that includes robust security measures, employee training, and careful planning for system integration.

How does digitalization improve product quality?

By enabling real-time monitoring and data analysis, digital technologies help detect defects early, optimize production parameters, and maintain consistent quality standards throughout the manufacturing process.

Where can I learn more about related technologies?

For further reading, explore topics such as understanding factory automation systems and how cloud computing helps factories to see how these innovations complement digital transformation in manufacturing.